What is emulation?

Emulation describes the ability of a system to realistically replicate the behaviour and functions of another system. This makes it possible to simulate operating systems, software or hardware with such precision that no original component is required for troubleshooting.

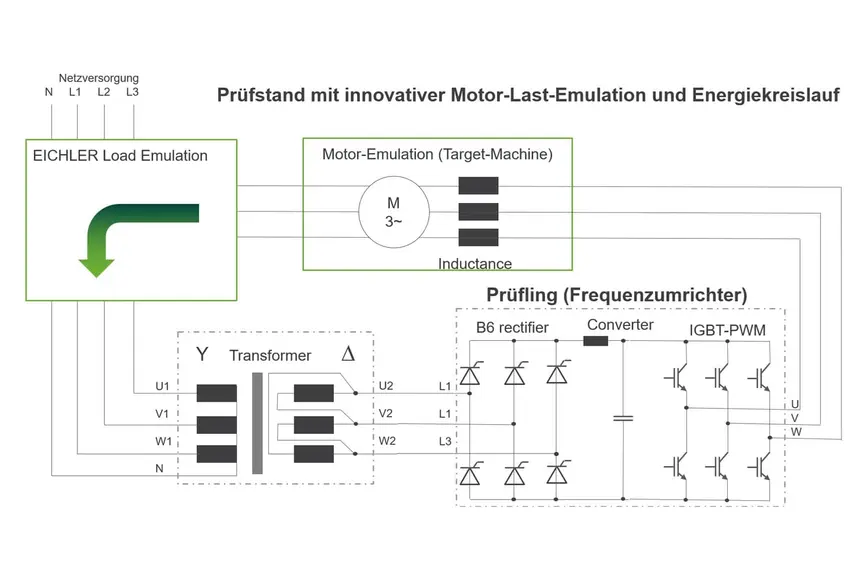

At EICHLER, a load emulator is used that accurately simulates a three-phase asynchronous motor. With the help of modern FPGA technologies, frequency converters or inverters can interpret the emulator's signals as if they were coming from a real motor, enabling testing without any physical hardware.

Key features:

- Configurable dynamic and load scenarios for frequency converters and inverters from various manufacturers (e.g. Siemens, Lenze, Danfoss, SEW, ABB, etc.)

- Maximum testing depth thanks to the electronic replication of real machine loads

- Warranty extension of up to 36 months

- Test report including all relevant test results