SIMATIC® S5 COMPACT - Handling and Troubleshooting

Seminar duration: 3 days, 8.00 a.m. - 5.00 p.m. | Cost per participant: 2,589 EUR plus VAT

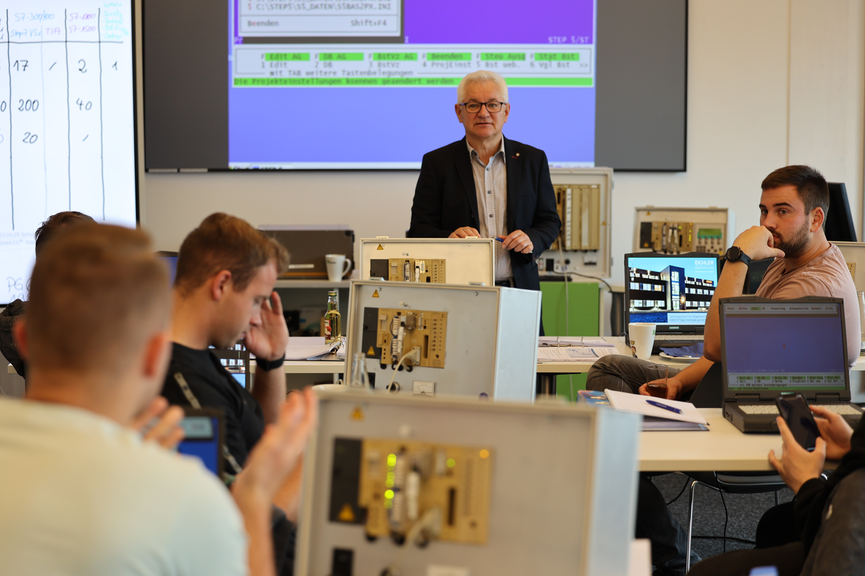

The new COMPACT seminar on SIMATIC® S5 COMPACT provides valuable fundamental knowledge on components, applications, and special features, as well as practical experience in dealing with faults over the course of 3 days.

Participants will learn to program independently and create functions using practical examples. To ensure effective learning, the practice programs are independently tested by each participant on test rigs.

The focus is on handling the programming device. Participants will learn the correct program settings and how to analyse output messages.

This is the ideal learning and training platform for young professionals who want to gain access to S5-controlled systems. Experienced maintenance personnel will benefit from practical fault resolution.

Using the unique fault simulation racks, realistic faults in hardware and software of a virtual S5 system will be worked on. From fault reading to complete component replacement and recommissioning, various practical applications will be learned under the guidance of experienced instructors.

Included services

- Detailed documents ?

- Catering ?

- Free parking places ?

It is the ideal learning and training platform for all professionals who want to gain access to S5-controlled systems.

A behind-the-scenes look at our EICHLERakademiE

EICHLER's specialist seminars are designed to be interactive, offer opportunities for networking, and are characterised by practical, hands-on topics.

Professionals and decision-makers from maintenance, procurement, and technical fields take the opportunity to stay informed about current topics, trends, and developments in areas such as automation technology maintenance, Life Cycle and Repair Management, or Obsolescence Management.

Dates

1Including materials, catering during the event. Travel and accommodation are not included in the price. Cancellation conditions: > 4 weeks = free; 2-4 weeks = 20%; < 2 weeks = 50%; < 1 day = 100% of the event price.

2 room contingents at special rates available upn request.

Book now!

Expert knowledge at your location

We also offer this seminar on-site.

- Content tailored to your needs

- No travel costs for your staff

- Training in a familiar environment

- Your team remains productive on site

- Exercises can also be carried out directly on your equipment