Increase system availability and reduce maintenance costs

Life Cycle Management

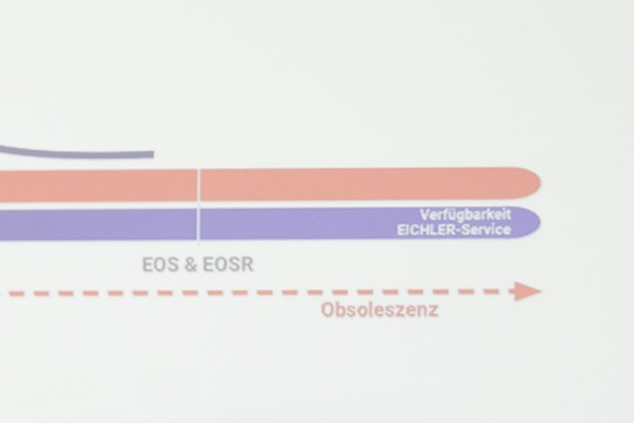

- Ensure long-term system availability

Prevents manufacturer-side obsolescence

- The EICHLER model: 3 modules for maximum flexibility

- From inventory assessment to supply strategy

- Personalised consultation by EICHLER experts

Life Cycle Management

Electronic assemblies are among the system and machine components with the shortest life cycles. On average, 5-7 years pass between market launch and discontinuation.

In combination with the increasing degree of automation, system operators and maintenance engineers are increasingly confronted with component obsolescence. As a leading service provider, EICHLER offers comprehensive Life Cycle Management solutions for industrial electronics, from touch panels to large inverters. Starting with the basic inventory through to the full service concept including warehouse management. This gives you as an operator the opportunity to act flexibly in order to identify dangerous gaps in your service cycle at an early stage and to ensure system availability with the help of tailor-made supply strategies until the planned decommissioning.