SIMATIC S7 COMPACT - Basic knowledge, system handling, troubleshooting

Seminar duration: 3 days from 8.00 a.m. - 5.00 p.m. | Cost per participant: 2,589 plus VAT

In this technical specialist seminar, participants acquire valuable specialist knowledge in the field of SIMATIC® S7 over three days.

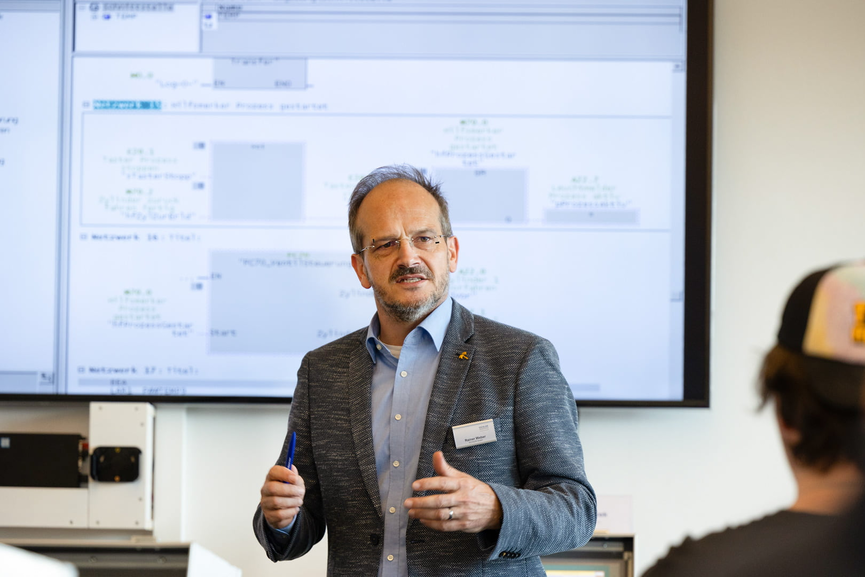

Participants are given an overview of the Siemens S7 device family and learn the basics of programming with the SIMATIC® Manager. With its help, participants learn all the steps involved in creating a system project step-by-step. This is followed by further exercises and tests on training racks. This also includes communication between modules via MPI or ProfiBUS connections. Participants are provided with important information on the use of programming devices and network technology.

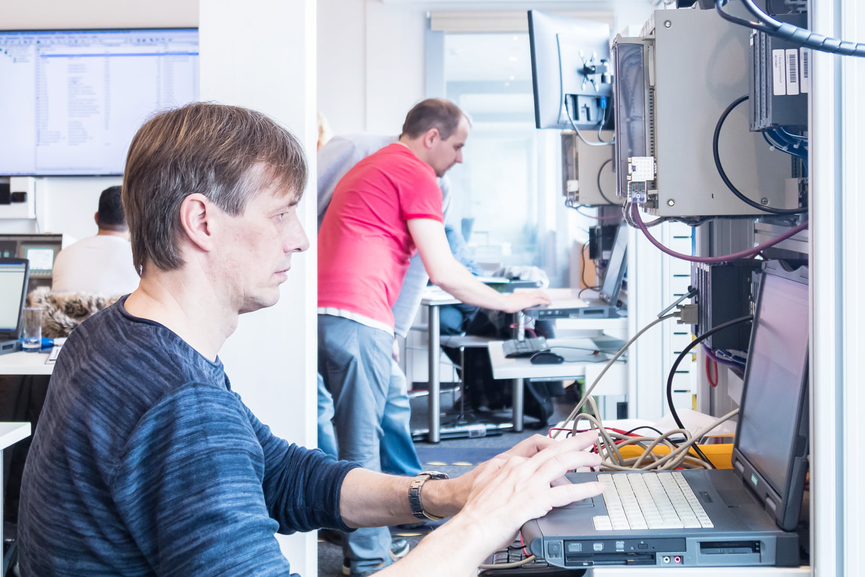

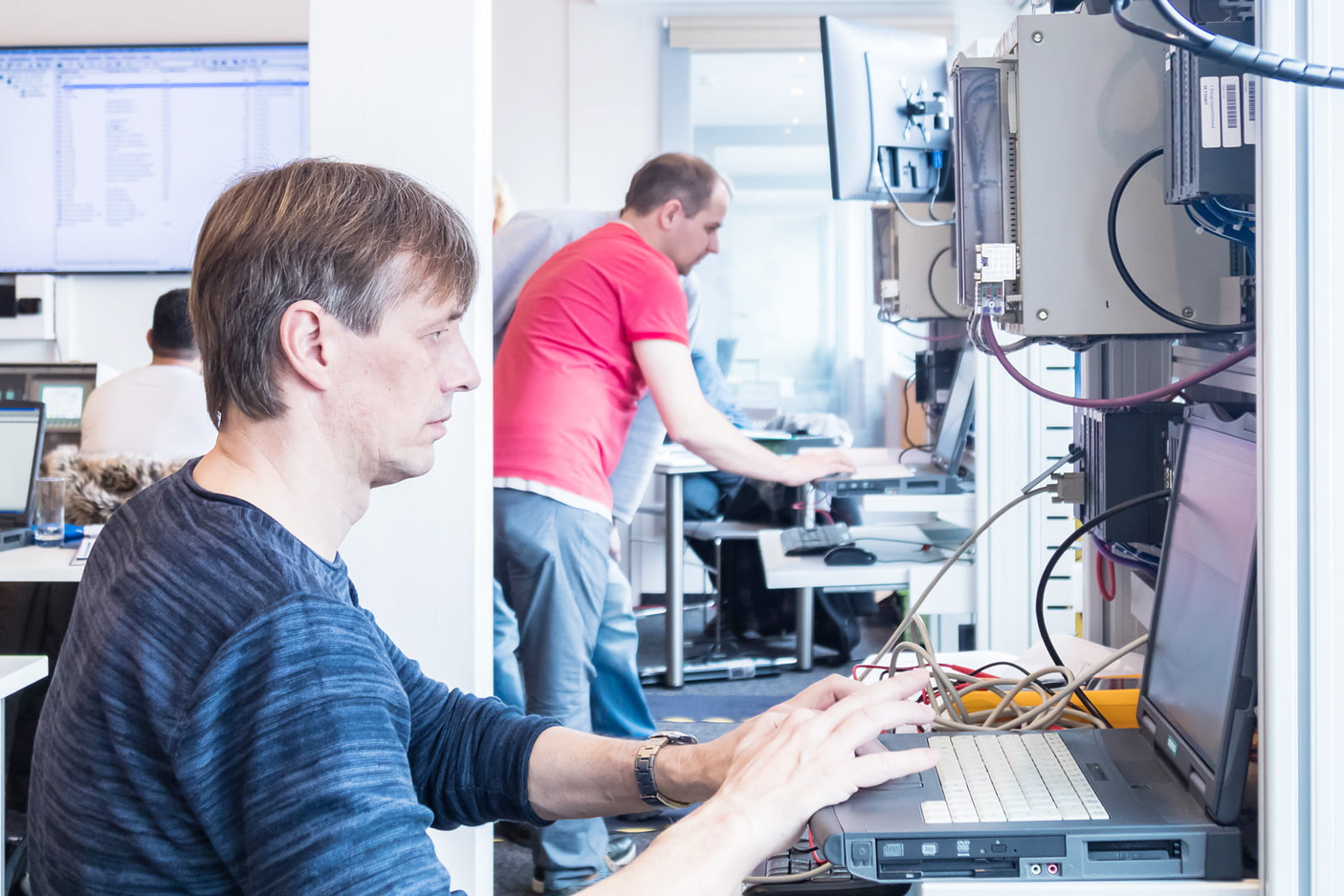

State-of-the-art error simulation racks developed in-house enable maximum practical benefit. The participants train their skills within a virtual S7 system, analyse error patterns, take measures to eliminate hardware and software errors and carry out recommissioning. Participants analyse and process realistic hardware and software faults in a virtual S7 system. Working with integrated special functions, alarm OBs and the diagnostic buffer facilitates the analysis. Once the fault has been rectified, the system is put into operation.

This seminar also provides knowledge and skills beyond the basics that are required to modify and optimise existing production systems. The participant optimises the Step7 program on a running production system.

Included services

- Detailed documents ?

- Catering ?

- Free parking places ?

The combination of experienced instructors and hands-on work with training racks and programming devices ensures maximum learning success.

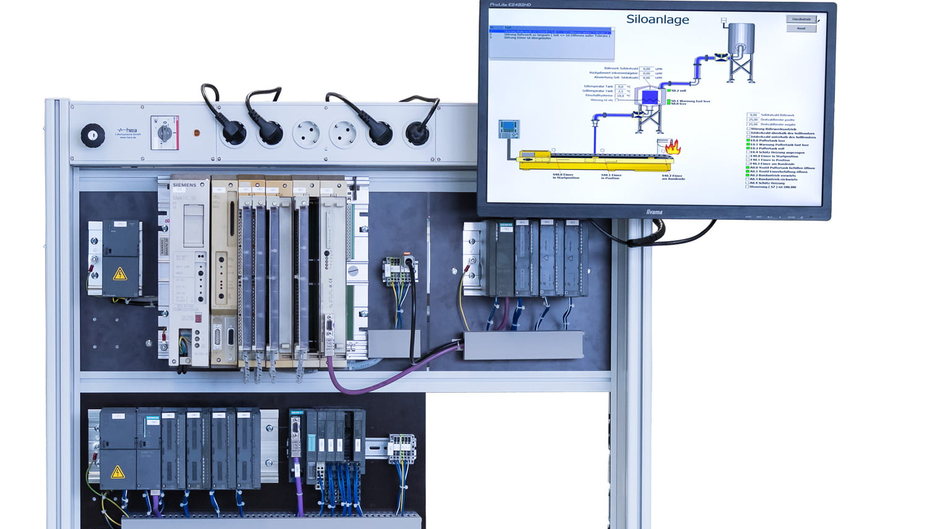

Unique training technology

Troubleshooting and fault elimination—trained as realistically as possible—was the guiding principle in the development of our fault simulation racks.

Our more than 40 years of experience and thousands of successfully completed repairs have flowed into the design. The result is a unique training technology that allows over 20 different fault scenarios to be simulated on the hardware and software of a virtual S7 system. It offers participants an ideal learning experience and maximum practical benefit.

A behind-the-scenes look at our EICHLERakademiE

EICHLER's specialist seminars are designed to be interactive, offer opportunities for networking, and are characterised by practical, hands-on topics.

Professionals and decision-makers from maintenance, procurement, and technical fields take the opportunity to stay informed about current topics, trends, and developments in areas such as automation technology maintenance, Life Cycle and Repair Management, or Obsolescence Management.

Dates

1 Includes materials and catering during the event. Travel and accommodation are not included in the price. Cancellation conditions: > 4 weeks = free of charge; 2-4 weeks = 20%; < 2 weeks = 50%; < 1 day = 100% of the event price.

2 room contingents at special rates are available upon request.