Determination of the individual assembly risk

Life Cycle Check

Risk analysis as part of the EICHLER Life Cycle Check

There are countless forms and methodologies of Risk Analysis available on the market that can provide insights into the condition of your machines and systems. However, they all share one common challenge: The need to painstakingly gather, collect, and store all relevant data over time before any meaningful results can be drawn from the complete configuration of your machinery and equipment.

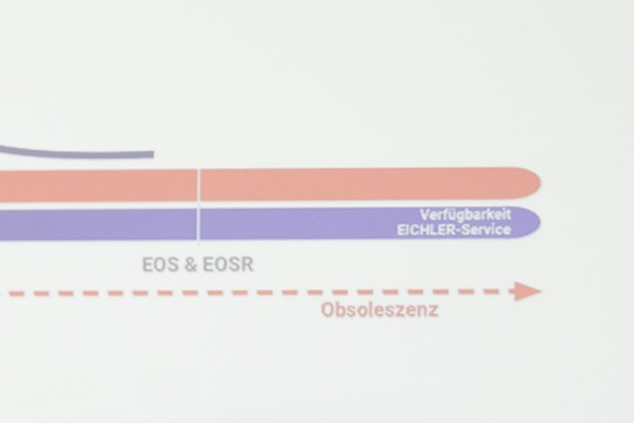

Understanding the current condition, historical development, and future outlook of individual units is crucial for effective Life Cycle Management - especially when it comes to developing a strategy to sustainably secure system availability in the face of obsolescence. Current standards and guidelines for obsolescence management already recommend conducting a risk analysis.

However, when having a closer look at the various forms of Risk Analysis, numerous obstacles become apparent. For example, in this area, time, resources, and the necessary expertise are often lacking - even for answering fundamental question such as: “Who is qualified to conduct a Risk Analysis?”, “When should a risk analysis be carried out?” and “What data is actually required to perform a meaningful risk assessment?”

For this reason, we offer you our expertise and experience in Obsolescence Management, either building on the inventory assessment we have already conducted together or based on the data you currently have available. Our continuous market analysis and monitoring enable us to provide valuable insights. Understanding how the market behaves, how it is evolving, and how it may develop in the future is critical for shaping a reliable supply strategy and planning ahead with confidence.