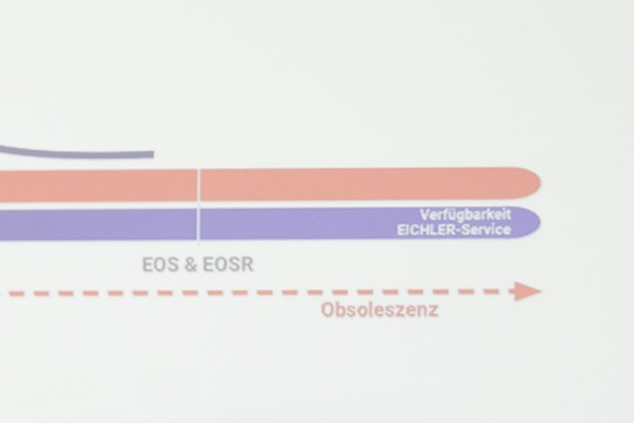

For the sustainable assurance of your system availability

Individual Supply Strategies

With the right supply strategy, you're on the safe side

Long, unplanned breakdowns are what manufacturing companies fear the most. High failure rates and the resulting costs are the consequences. The difficult task of avoiding such situations often falls to the maintenance departments, which typically have limited resources, time, and means to handle these challenges successfully under optimal conditions. But where do the specific problems lie that still lead to prolonged breakdowns? Is it due to missing or incorrectly planned inventory, sourcing obsolete or temporarily obsolete spare parts through manufacturers, machine builders, and service providers, or perhaps the insufficient budget for stocking and maintaining spare parts? Unfortunately, it is the combination of all these and many other hurdles that make maintenance so complex today.

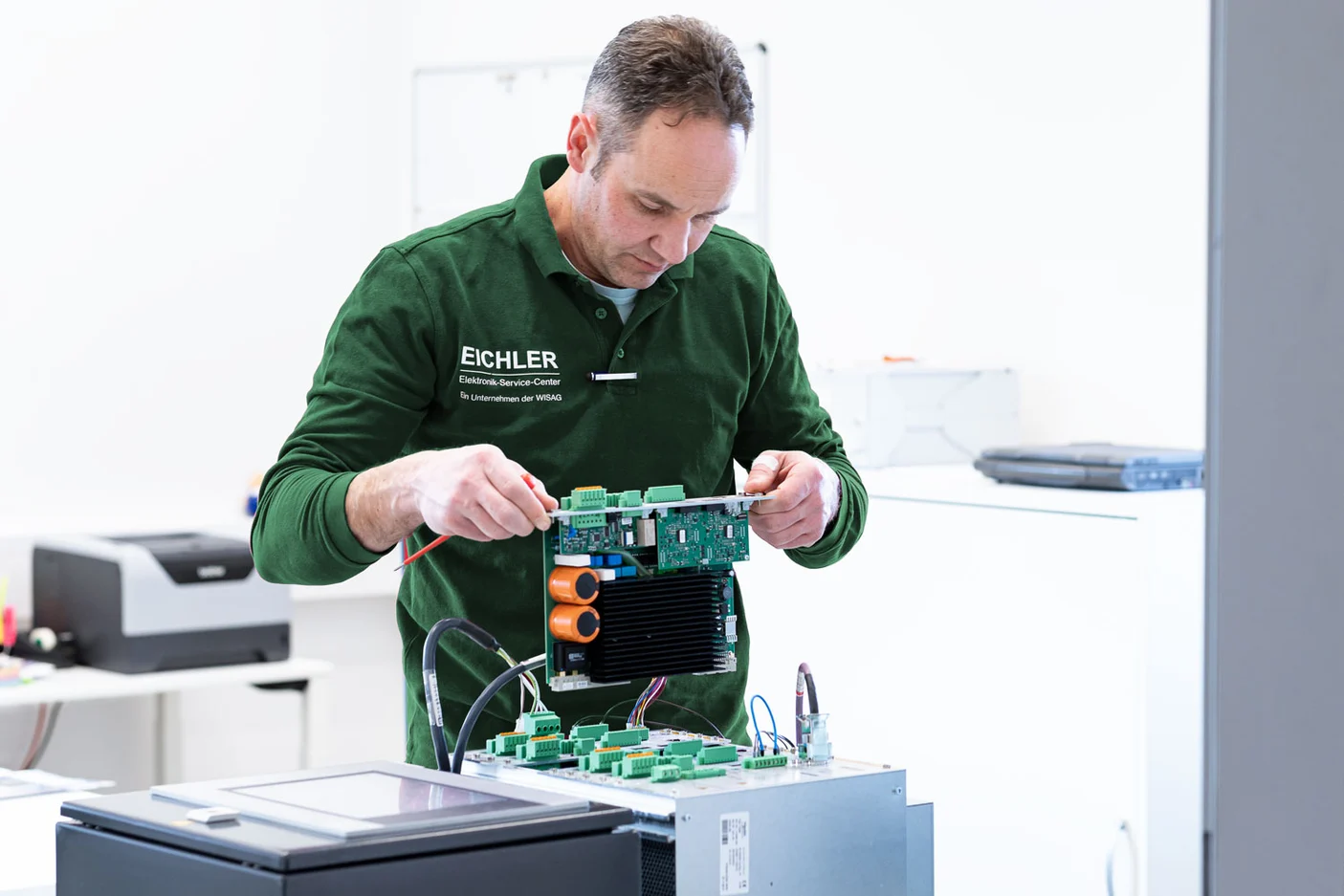

This is why EICHLER GmbH focuses on process-oriented, customised supply strategies that can be flexibly integrated into nearly any company to gradually address individual problems and thereby support your maintenance department with targeted actions. To ensure quick response times in your production, the solution often lies in a supply strategy mix—combining efficient inventory management with proactive preventive measures and professional repairs. Within these supply strategy combinations, there are additional tasks that might be difficult to manage independently. For example, creating ideal storage conditions is not always easy, and in some cases, it may seem nearly impossible to implement. When it comes to long-term storage of electronic units, the key is finding the right mix in Inventory Management to meet the specific requirements of individual components. For example, from a purely physical standpoint, some materials within electronic components should ideally be stored under high humidity, while others are best kept in a vacuum.

Full-Service Warehouse Management is the most frequently requested supply strategy mix

Full-Service Warehouse Management is the most frequently requested supply strategy, and for good reason. As the name "Full-Service" suggests, this type of service already includes the necessary supply strategy mix. The basic principle is based on functioning Inventory Management. The stored units are in your possession, either already available or purchased later. The Inventory Management is shared between you and EICHLER, meaning you maintain a safety stock to respond quickly, while EICHLER keeps the remaining stock. These inventories are subject to the necessary technical tasks required to keep a unit functional while in storage. EICHLER works with you to create a concept that includes regular technical maintenance tasks. These measures apply to both the stock held by EICHLER and the stock you maintain. As a result, your inventory is constantly updated, and functionality is ensured. If a defect occurs in your machine or system, you can quickly respond with a 100% functional unit. You fix the defect and notify EICHLER that your stock needs to be replenished. Afterward, you send your defective unit to us for repair, and we can restore the original condition by returning it to your EICHLER stock. If a unit is irreparable, we will always try to source a new one and integrate it into the concept. If your requirements change, this concept is flexible enough to accommodate such changes, allowing the overall quantity to be adjusted upward or downward at any time.