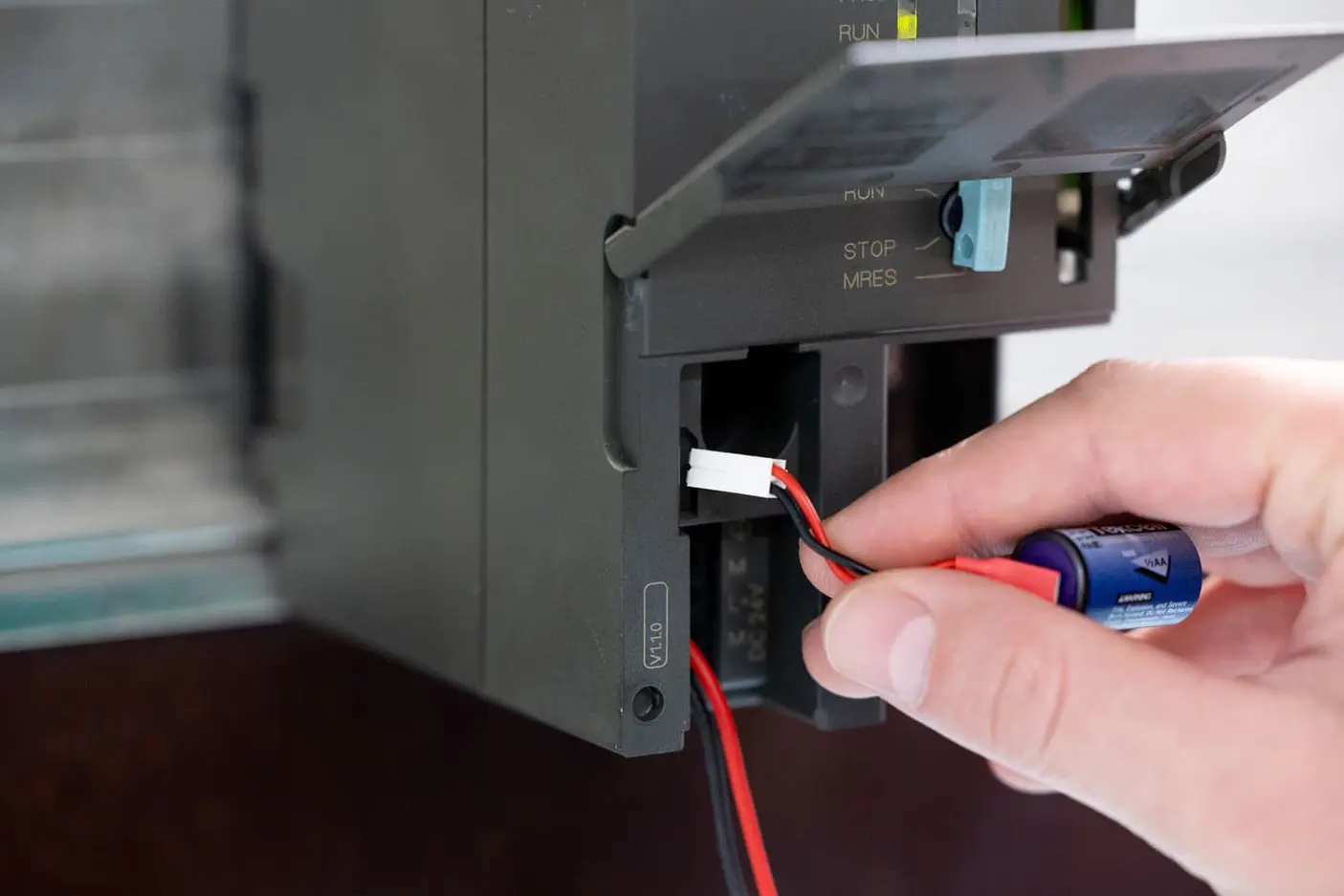

Key information on replacing the buffer battery in the S7-300

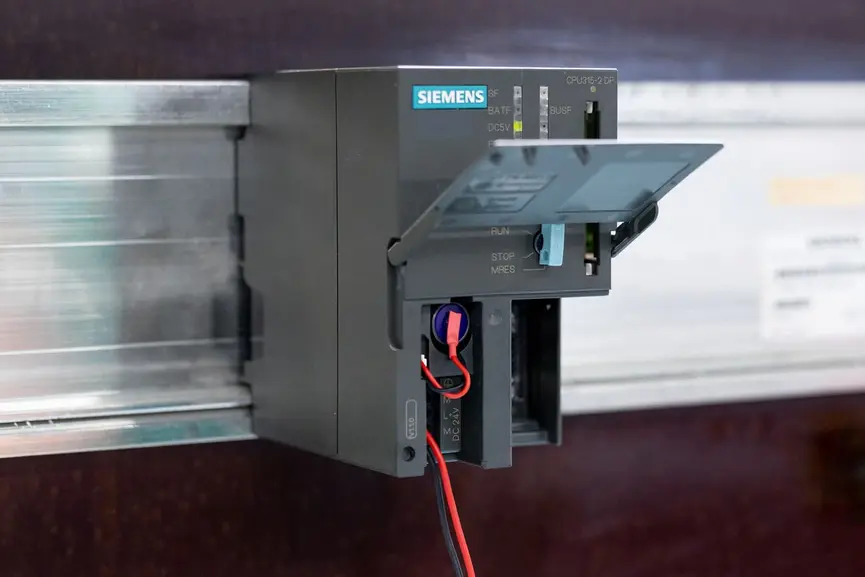

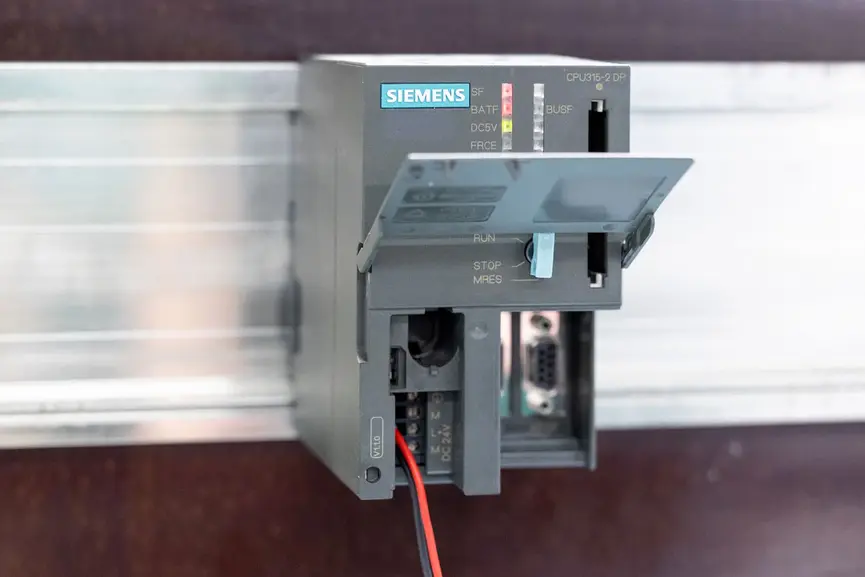

- Replace the battery only when the CPU is switched on.

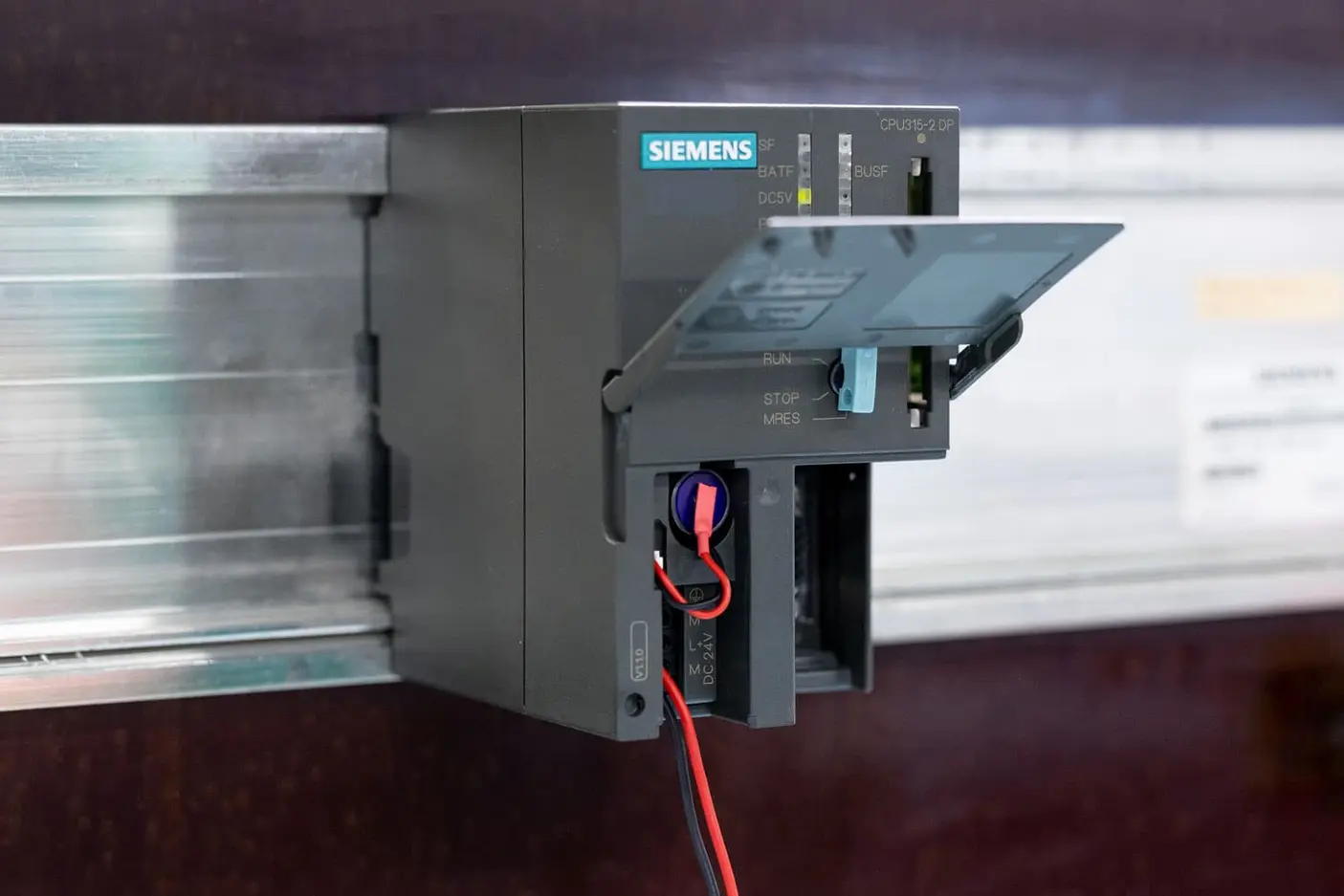

- Preferably carry out the replacement as part of scheduled maintenance.

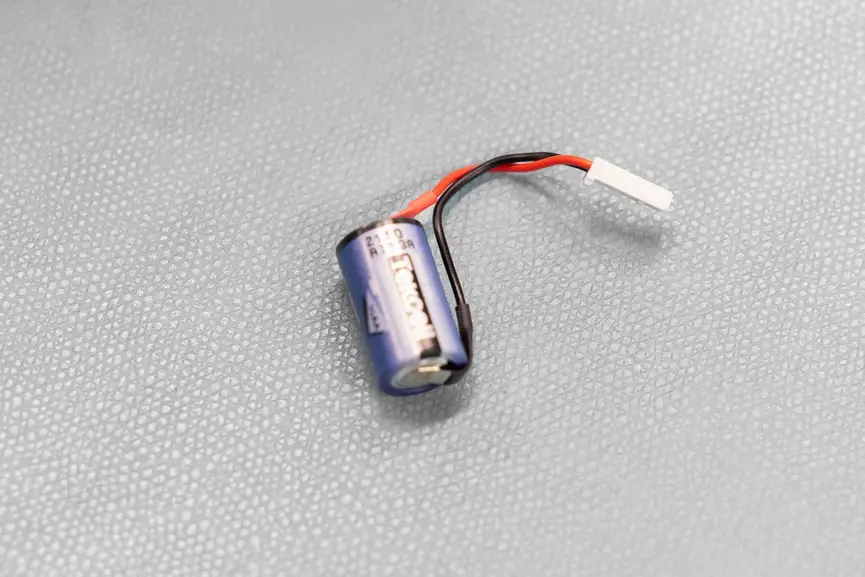

- Renew the batteries every 3 to 5 years - depending on operating time and environmental conditions.

- Store spare batteries in a dry, cool place; do not keep them loose in a toolbox.

- If the BATF message reappears repeatedly, check the power supply or buffer capacitor.