EICHLER expands service for Swiss customers

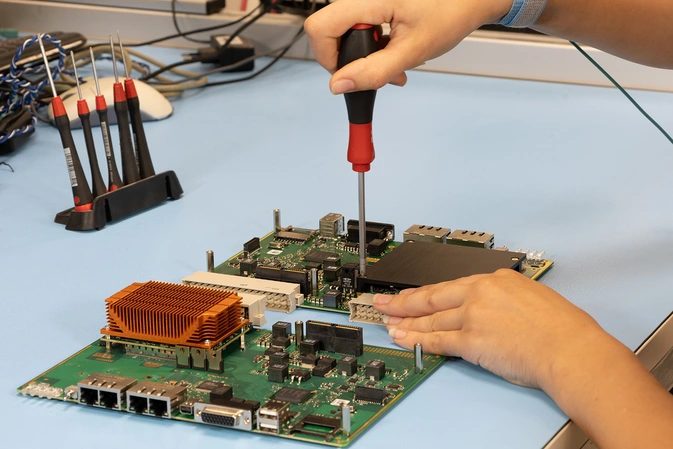

Thanks to the partnership between EICHLER and REASCO, faulty components can now be shipped easily within Switzerland. Both companies are part of the WISAG Group and leverage existing synergies to further expand their service offerings in the region. REASCO handles the forwarding to the EICHLER Electronics Service Center in Germany, while EICHLER manages the entire customs clearance process. This means less effort, lower costs, and faster processing.

The collaboration with REASCO ensures that repair shipments are handled safely and efficiently. This not only reduces waiting times but also significantly lowers shipping costs. This is a great relief, especially for companies with a high degree of automation.