A reliable partner provides rapid assistance

The call to EICHLER, one of the leading repair service providers for automation technology, marked the turning point. EICHLER, known for its expertise and ability to carry out even the most complex repairs in record time, offered immediate support.

Claudio Giuppone recalls: ‘It was a quiet week until, at 5.30 p.m. on Thursday, I received an urgent call. I was on standby duty and had just gone shopping after work when my company mobile rang. An anxious English-speaking customer was on the line. His production press had come to a standstill, and he was in urgent need of a replacement for a defective ABC-IT control board.’

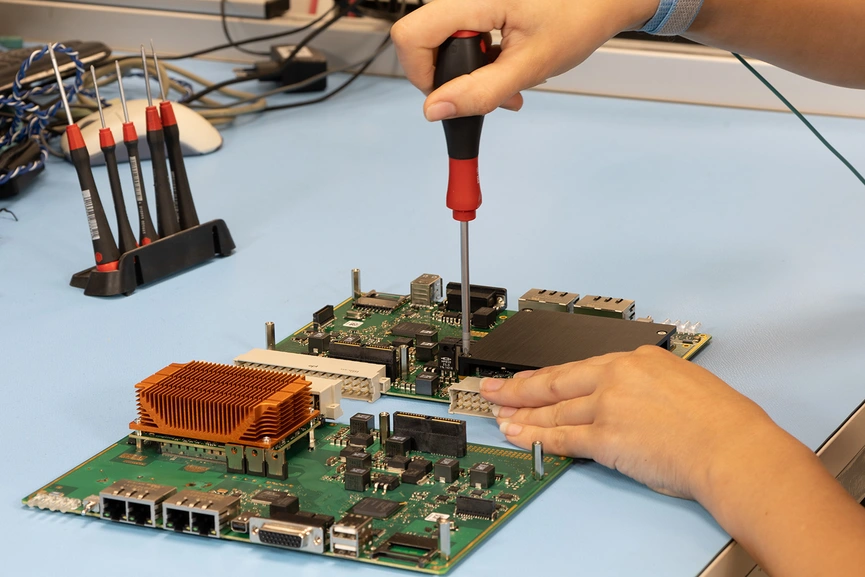

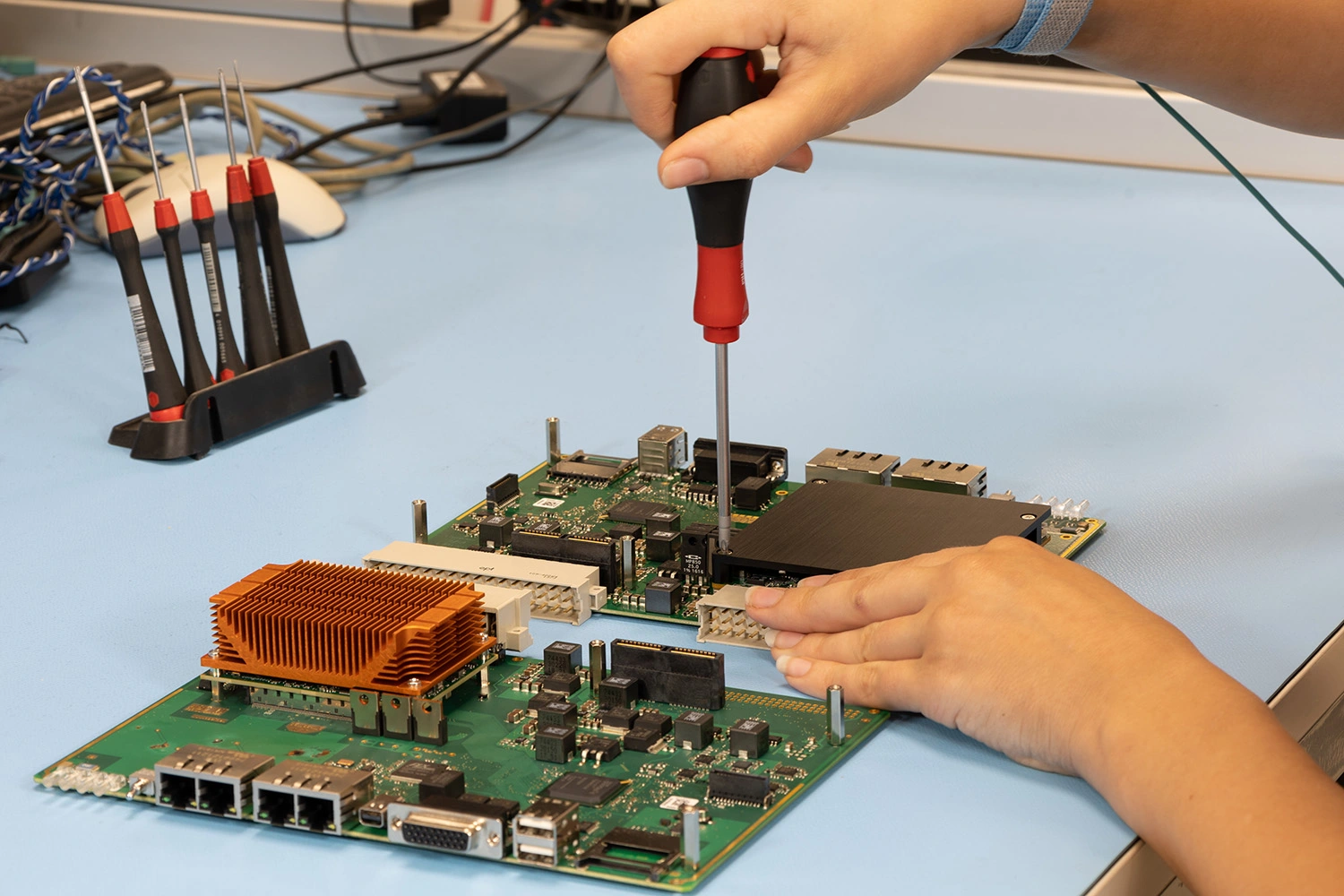

Claudio quickly set his hopping trolley aside, left the supermarket, got into his car and opened his company laptop. ‘I calmed the customer down and assured him that we would find a solution,’ he remembers. ‘Although we didn’t have the board on stock, I knew our technical team would be able to repair the defect.'

The customer, Luís Malheiro, was relieved, but stressed that the repair needed to take place ‘TODAY’, as every minute of standstill was costly. When Claudio suggested organising a direct courier, Mr Malheiro replied firmly: ‘I will get on a plane and bring the defective board to you myself.’

Without hesitation, Luís Malheiro set off for the airport in Portugal early the next morning. Just a few hours later, he personally delivered the defective control board to EICHLER's repair centre.