What is Reengineering?

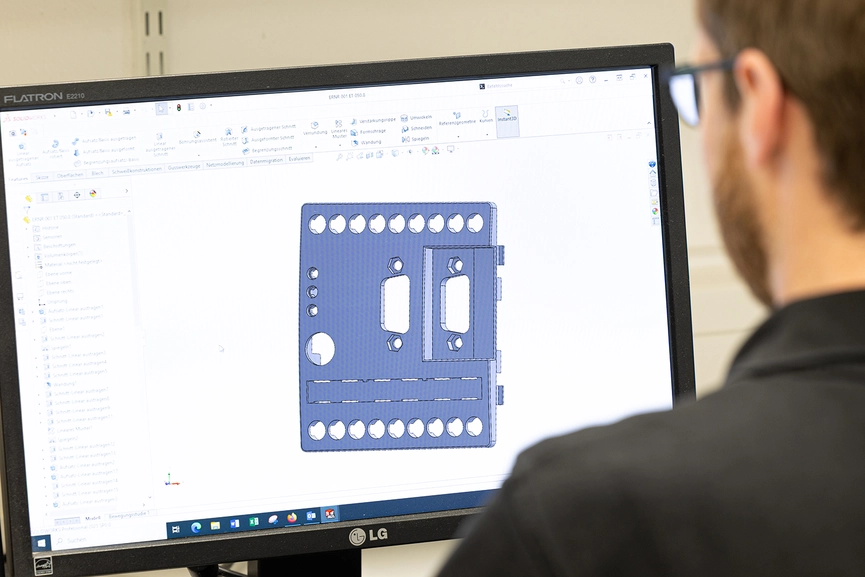

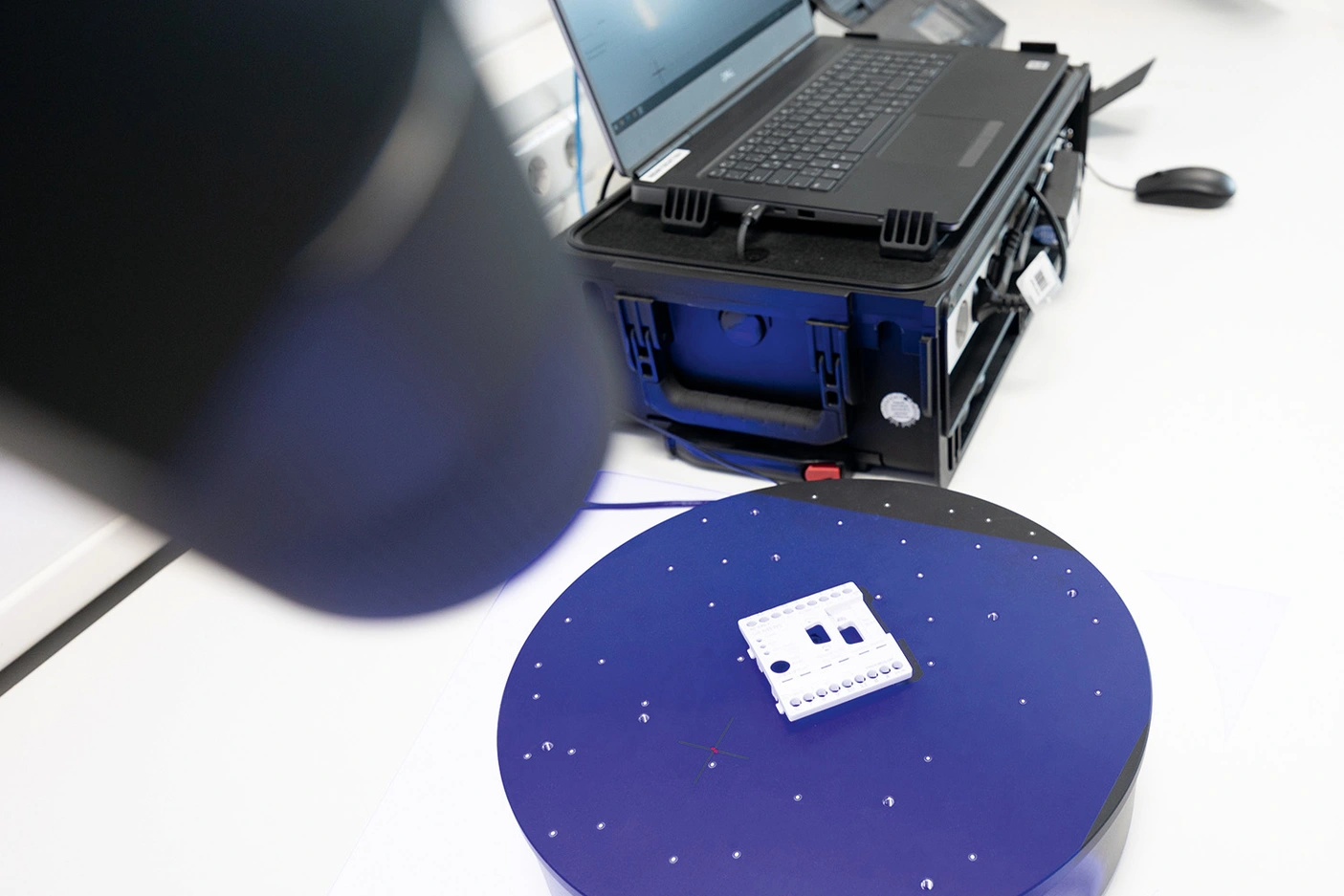

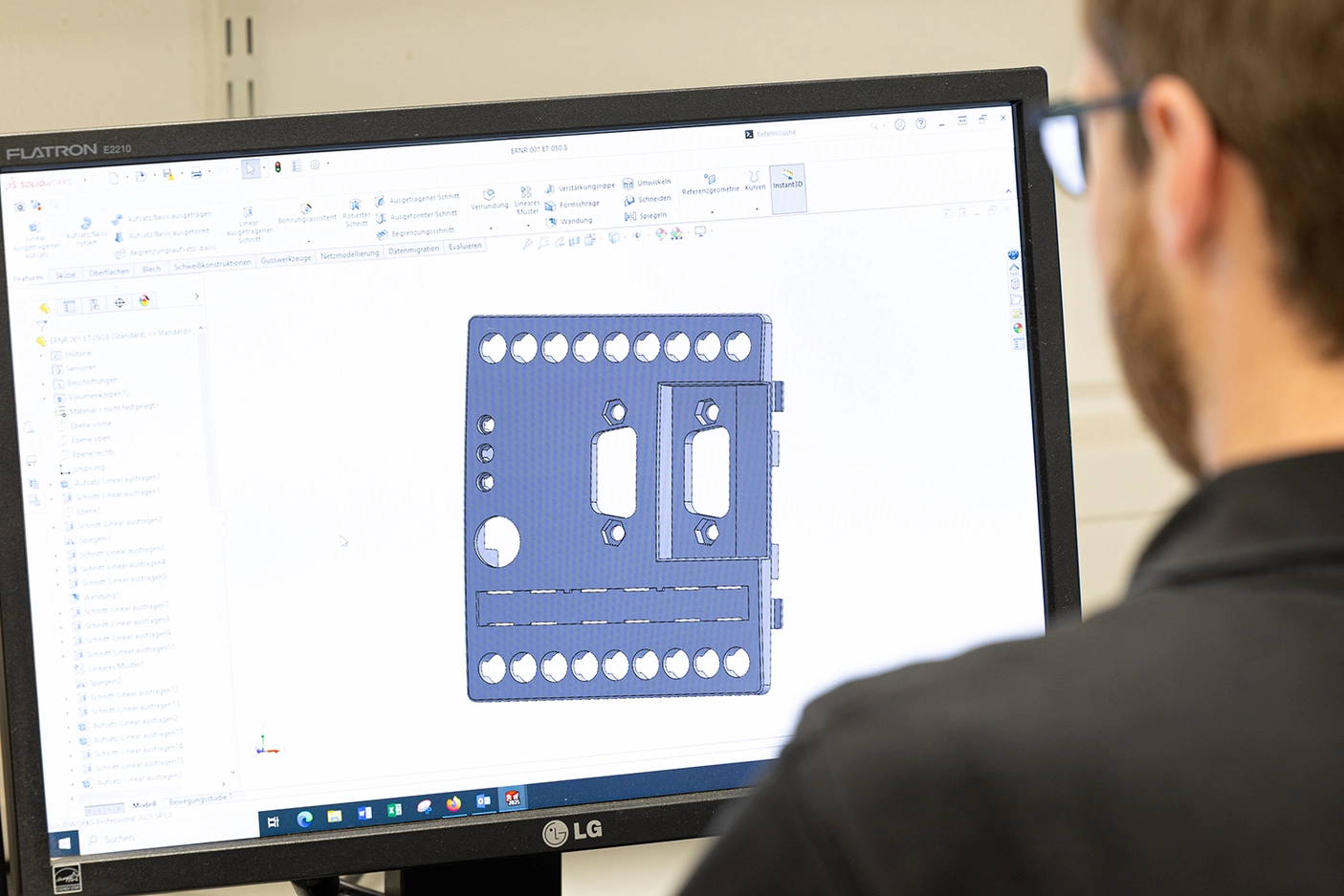

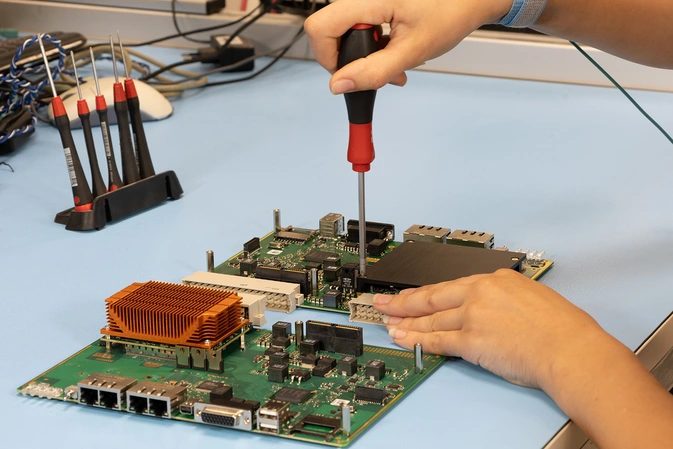

Reengineering is an innovative process through which we at EICHLER reproduce components that are no longer available or no longer manufactured, using advanced production technologies. Especially in industries where systems are designed for long service lives, but devices are eventually discontinued, no longer supported, or no longer supplied with spare parts. reengineering provides a valuable solution - all to maintain repairability for as long as possible.

When housings, electronic components, or other parts disappear from the market, we make it possible to restore these parts to full functionality and integrate them into existing systems or devices. By applying stat-of-the-art technologies, we create near-identical reproductions with the same functions and characteristics as the original.