Obsolescence Management

Seminar duration: 1 day, 9.00 a.m. - 5.00 p.m. | Cost per participant: 729 EUR plus VAT

The correct definition of Obsolescence Management is essential for companies that aim to generate significant returns and profits with fully depreciated production equipment. It focuses on the risks associated with the permanent unavailability of products, such as when the production of original parts is discontinued.

This seminar highlights the causes and impacts of obsolescence in the industrial environment. It is specifically tailored to topics in production and maintenance. Participants will learn efficient measures and strategies from Obsolescence Management. Numerous practical case studies and workshops provide the opportunity to apply the knowledge gained directly. Interaction with professionals and managers from various industries will provide new insights for implementation within the company.

Included services

- Detailed documents ?

- Catering ?

- Free parking places ?

Secure your equipment availability against component obsolescence and discontinuations.

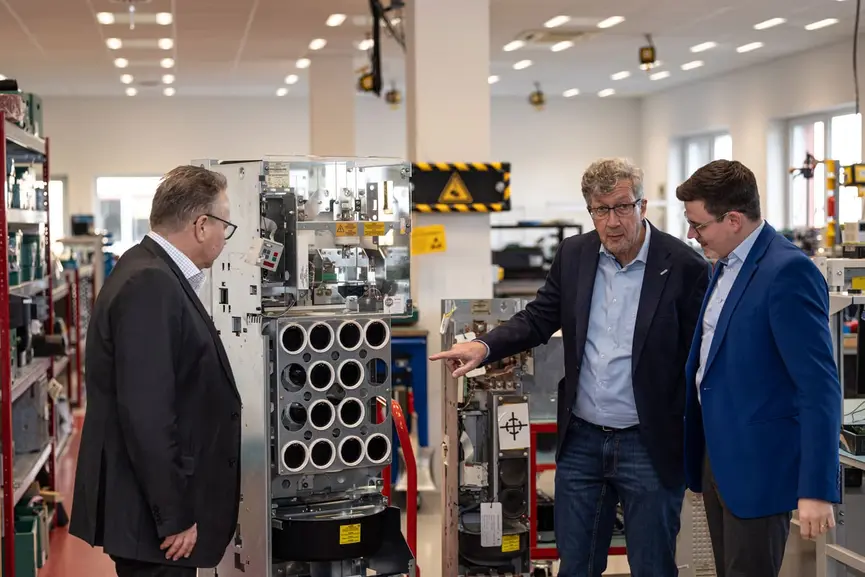

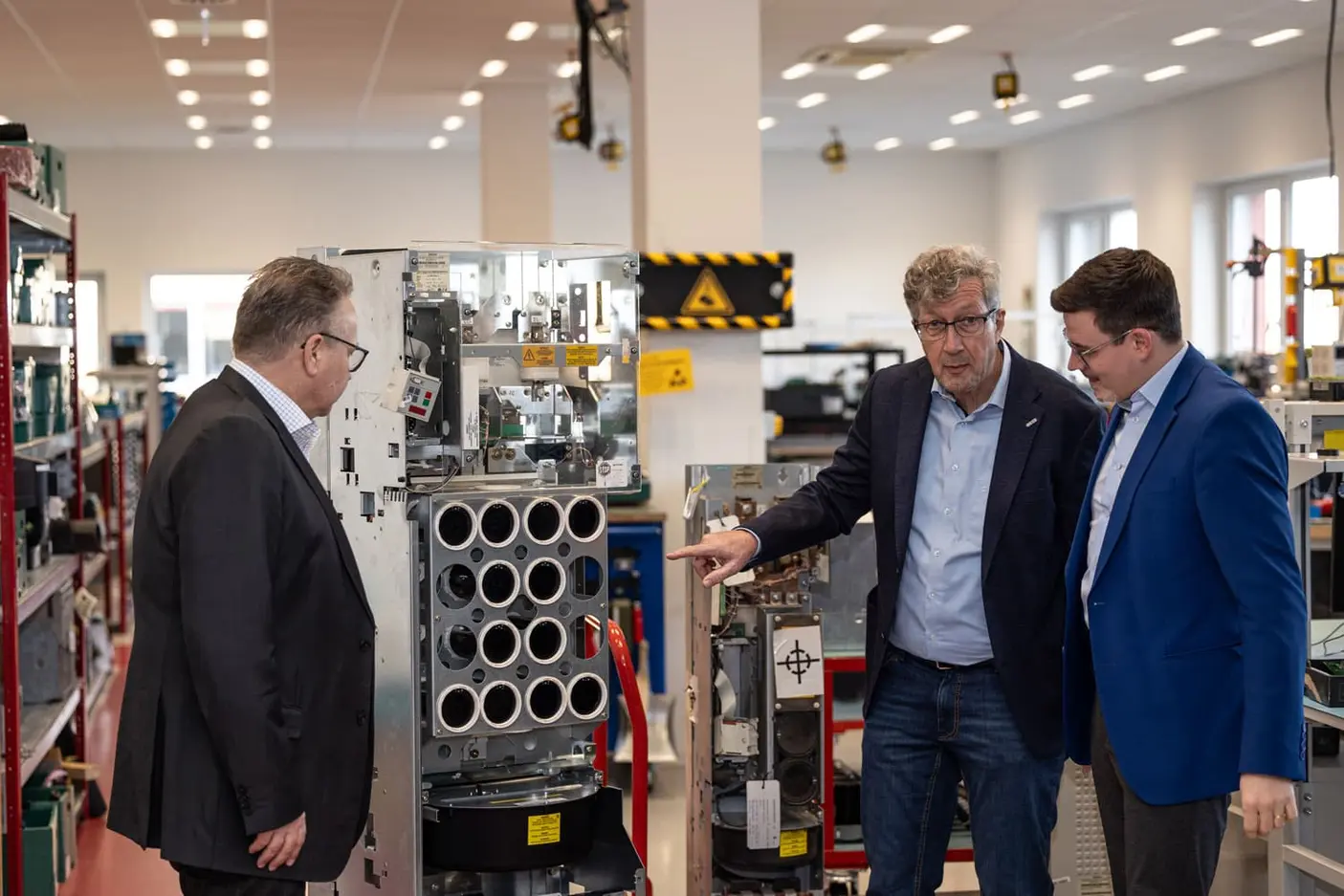

A behind-the-scenes look at our EICHLERakademiE

EICHLER's specialist seminars are designed to be interactive, offer opportunities for networking, and are characterised by practical, hands-on topics.

Professionals and decision-makers from maintenance, procurement, and technical fields take the opportunity to stay informed about current topics, trends, and developments in areas such as automation technology maintenance, Life Cycle and Repair Management, or Obsolescence Management.

Dates

1 Including materials, catering during the event. Travel and accommodation are not included in the price. Cancellation policy: > 4 weeks = free; 2-4 weeks = 20%; < 2 weeks = 50%; < 1 day = 100% of the event price.